The Material Selection Guide

Here’s a strong one-sentence hook you can use: Choose the right material every time with this guide that simplifies CNC material selection and helps engineers balance performance, cost, and compliance.

Get it straight to your inbox

What's inside?

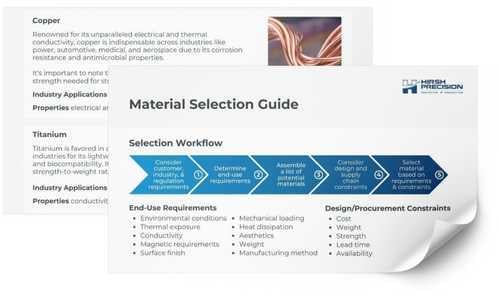

This guide provides engineers with a step-by-step approach to selecting metals for CNC-machined parts, focusing on end-use needs like performance and durability, while also considering practical factors such as cost and material availability.

The guide profiles commonly used metals—including aluminum, steel, stainless steel, brass, copper, and titanium—highlighting their properties, machinability, and ideal applications across aerospace, medical, industrial, and semiconductor sectors. You’ll gain insights into strength-to-weight ratios, corrosion resistance, and thermal performance to make informed decisions that balance functionality and manufacturability.

Whether you’re designing lightweight aerospace parts or high-conductivity medical components, this guide helps you select materials that meet performance and compliance standards.

Let's connect

Want to learn more about our CNC machining services? Schedule a time to speak with our team.